Wholesale Price Portable Photosensitive Dry Film - Dry Film Applied On FPC And PCB – Lucky Innovative

Wholesale Price Portable Photosensitive Dry Film - Dry Film Applied On FPC And PCB – Lucky Innovative

Wholesale Price Portable Photosensitive Dry Film - Dry Film Applied On FPC And PCB – Lucky Innovative Detail:

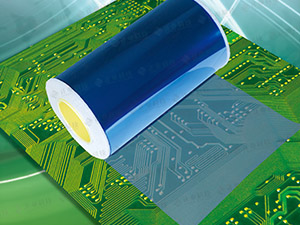

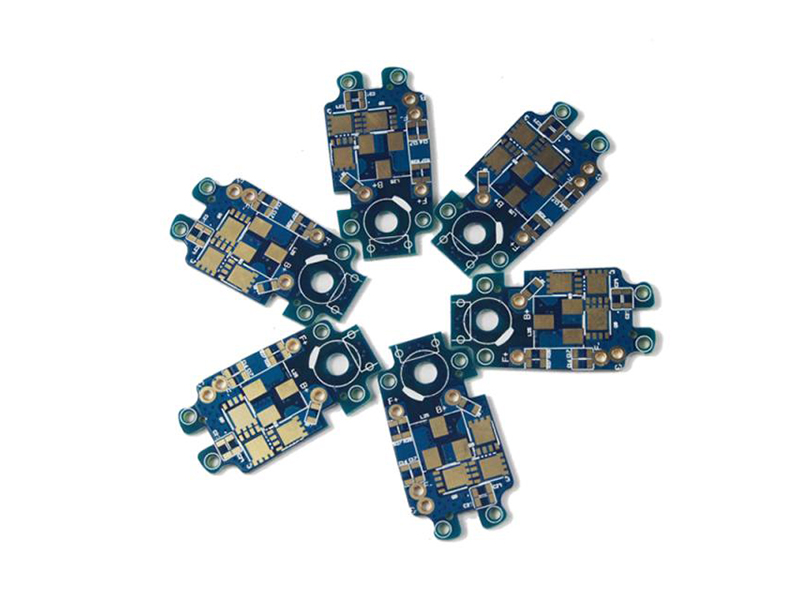

Product Application

Applied to Printed Circuit Board and Flexible Printed Circuit Board, with the advantage of excellent performance of tending, resolution and adhesion.

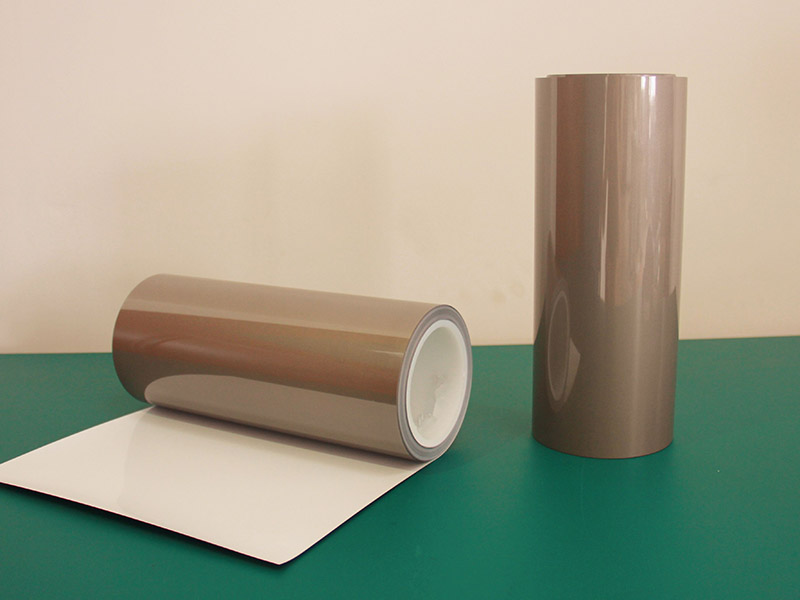

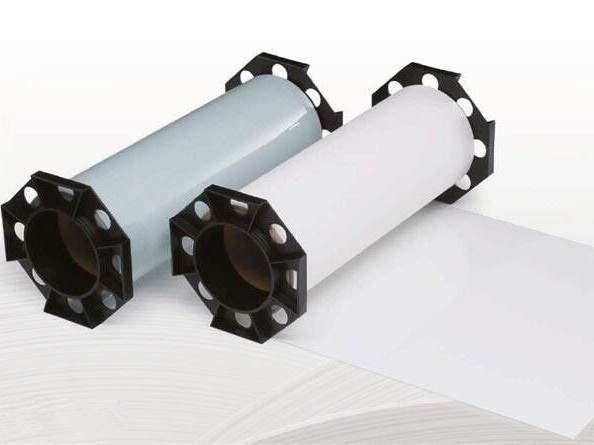

Product Structure

Product Specification

|

Product Code |

LK-D1238 LDI Dry Film |

LK-G1038 Dry Film |

|

Thickness (μm) |

38.0±2.0 |

|

|

Length (m) |

200m |

|

|

Width |

According to customers’ request |

|

Product Parameters

(1)LK-D1238 LDI Dry Film

LK-D1238 LDI Dry Film is suitable for direct imaging exposure machine, with wavelength both 355nm and 405nm .

|

Item and Test method |

Test Data |

|||

|

Shortest imaging time (1.0wt.% Na2CO3 water solution, 30℃) *2 |

25s |

|||

|

Wavelength (nm) |

355 |

405 |

||

|

Performance after Imaging |

Photosensitivity (*2×2.0) |

ST=7/21 Exposure energy*3 |

20mJ/cm2 |

15mJ/cm2 |

|

Resolution(*2×2.0) |

ST=6/21 |

40μm |

40μm |

|

|

ST=7/21 |

40μm |

40μm |

||

|

ST=8/21 |

50μm |

50μm |

||

|

Adhesion(*2×2.0) |

ST=6/21 |

50μm |

50μm |

|

|

ST=7/21 |

40μm |

40μm |

||

|

ST=8/21 |

35μm |

35μm |

||

|

【Tending Reliability】*3 10 holes (6mmφ) Rate of hole breaking (*2×2.0×3 times) |

ST=6/21 |

0% |

0% |

|

|

ST=7/21 |

0% |

0% |

||

|

ST=8/21 |

0% |

0% |

||

|

Striping end time (3.0wt.%NaOH water solution, 50℃) |

ST=7/21* 1 Exposure energy |

50s |

50s |

|

(2)LK-G1038 Dry Film

LK-G1038 Dry Film is suitable for contacting exposure machine, with main wavelength 365nm.

|

Item and Test method |

Test Data |

||

|

Shortest imaging time (1.0wt.% Na2CO3 water solution, 30℃) *2 |

22s |

||

|

Performance after Imaging |

Photosensitivity (*2×2.0) |

ST=8/21 Exposure energy*3 |

90mJ/cm2 |

|

Resolution (*2×2.0) |

ST=6/21 |

32.5μm |

|

|

ST=7/21*1 |

32.5μm |

||

|

ST=8/21 |

35μm |

||

|

Adhesion (*2×2.0) |

ST=6/21 |

45μm |

|

|

ST=7/21 |

40μm |

||

|

ST=8/21 |

35μm |

||

|

(Tending Reliability)*3 10 holes (6mmφ) Rate of hole breaking (*2×2.0×3 times) |

ST=6/21 |

0% |

|

|

ST=7/21 |

0% |

||

|

ST=8/21 |

0% |

||

|

Striping end time (3.0wt.%NaOHwater solution, 50℃) |

ST=7/21*1 Exposure energy |

50s |

|

(The above data is only for reference)

Note:

*1: Stouffer 21 Stage Exposure Energy Scale.

*2×2.0: Image with twice time of shortest imaging time.

*3: If focus on the Tending Reliability, it is recommended to use the exposure energy value of 7~8 stage.

*4: The above data is tested by our own equipment and instruments.

Application Process

Caution In Application

(1) Application : Use this film only as resist for printed circuit board-related material and other pattern formations.

(2) Pretreatment : Organic residues, stains due to insufficient dewatering and drying on the copper surface, may cause polymerization of resist and penetration of plating or etching solution.Please dry completely after water rinsing. Especially, when the moisture remain inside the through hole, it cause the tent breakage.

(3) Substrate preheating : Preheating at too high temperature for a long time may cause rust.It should be done for less than 10 min at 80℃ and for less than 3 min at 150℃. And when the substrate surface temperature prior to lamination exceeds 70℃, the film thickness on a through-hole edge may become too thin and it may cause tenting breakage.

(4) Holding after lamination and exposure : Hold with the light shield or under yellow lamp (2 meters or more distance required). The maximum holding time in the latter case (under a yellow lamp) is 4 days. Exposure should be done within 4 days after lamination.Development should be done within 3 days after exposure. Ray of non-ultraviolet white lamp has some ultraviolet rays, so hold with the light shield by black sheet under it.Keep temperature 23±2℃ and relative humidity 60±10%RH. Laminated substrates should be put in a rack one by one.

(5) Development : When temperature of developer is over 35℃, it may make resist profile worse.

(6) Stripping : Strip within one week after lamination.

(7) Waste treatment : Dry film components in developer and stripper can be coagulated by neutralization. The coagulated components can be separated from the aqueous solution by filter press method and centrifugal method. The separated aqueous solution has some COD and BOD values, so it has to be waste-disposal treated in a proper way.

(8) Film color : The color is green/blue. Though the color may gradually discolor with time, it should not influence the characteristic.

Caution On Storage

(1) When storage is done in a dark, cool, and dry place at the temperature of 5~20℃ and relative humidity of 60%RH or lower, dry film should be used within 50 days after manufacture.

(2) Keep film rolls horizontally by using of racks or support boards for storage. When they are laid vertically, sheets of dry film may slip one by one and roll-shape may be like a bamboo sprout (rolls are laid down horizontally in a package).

(3) Take out film rolls from black sheet under a yellow lamp or the same kind of safety lamp. Do not leave them under the yellow lamp for a long time. Cover film rolls by black sheet when you store them for a long time.

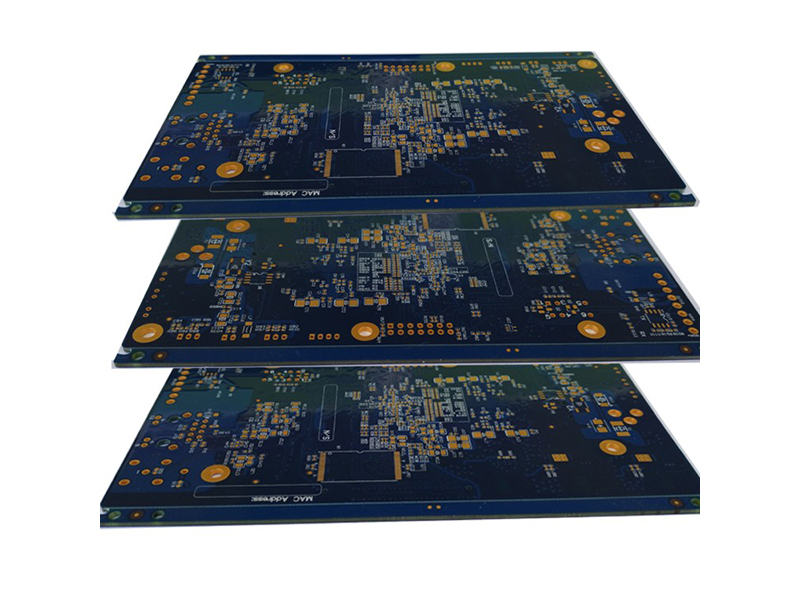

Product detail pictures:

Related Product Guide:

Our goal is to satisfy our customers by offering golden service, good price and high quality for Wholesale Price Portable Photosensitive Dry Film - Dry Film Applied On FPC And PCB – Lucky Innovative , The product will supply to all over the world, such as: Hamburg , Israel , Philadelphia , Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.